The process of PCB Depaneling can be prosecuted via easy-to-handle manual Depaneling Pliers or by using automated complex PCB Depaneling Systems.

In the high-volume electronics assembly production the Panel stands for a PCB (printed circuit board), that consists of many smaller individual PCBs that will be used in the final product.

The panel may comprise identical circuit functions with the same structure or different circuit functions on single boards.

A production panel comprises at least two single PCBs. The large panel is broken up or “depaneled” in a certain step on the process. This process step is called Depaneling or PCB Separation.

Here we would like to present 2 possible depaneling methods:

- Manual Depaneling Pliers

- DPF 200 Depaneling System

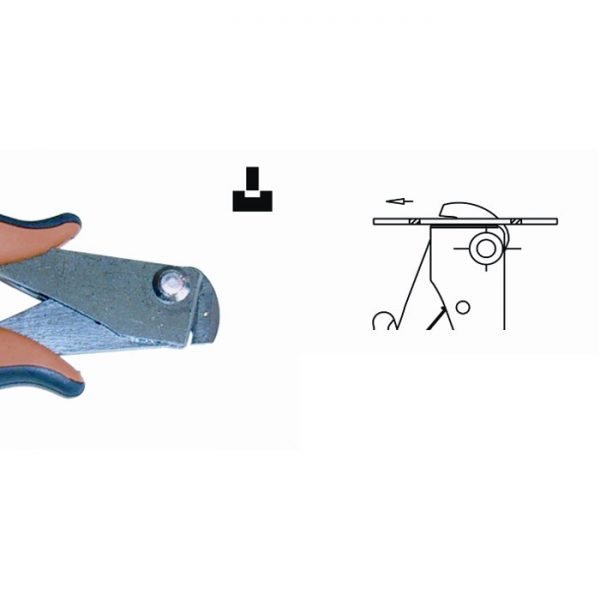

Manual Depaneling Pliers

The manual depaneling pliers is a hand tool suitable for strain-resistant circuits (e.g. without SMD components). The operator simply breaks the PCB, usually along a prepared V-groove line, with the help of a proper fixture.

This is a safe way to depanel, which leaves a smooth cutting surface.

The isthmus (that means the width of the conncting part shall not exceed 2,5 mm and the maximum PCB thickness shall not exceed 2 mm.

Ideal transmission of power and an excellent ergonomical handling garantuees the quality we are used from products by Piergiacomi.

DPF 200 Depaneling System

This newly designed manual workdesk is the ideal tool to depanel quickly and safely using a saw – especially if the investment for a fully-automated application is to expensive.

The rail system equipped with a saw, applied for a patent, supports the user to work with on a consistent quality level.

Already mounted parts on the panel do not get harmed.

The cut width of the replaceable rail ranges from 1,5mm – 2,5mm, the maximum PCB thickness shall not exceed 2,5 mm.

You can order the Depaneling System conveniently in our Toolshop!

Have a look at our short demonstration video: