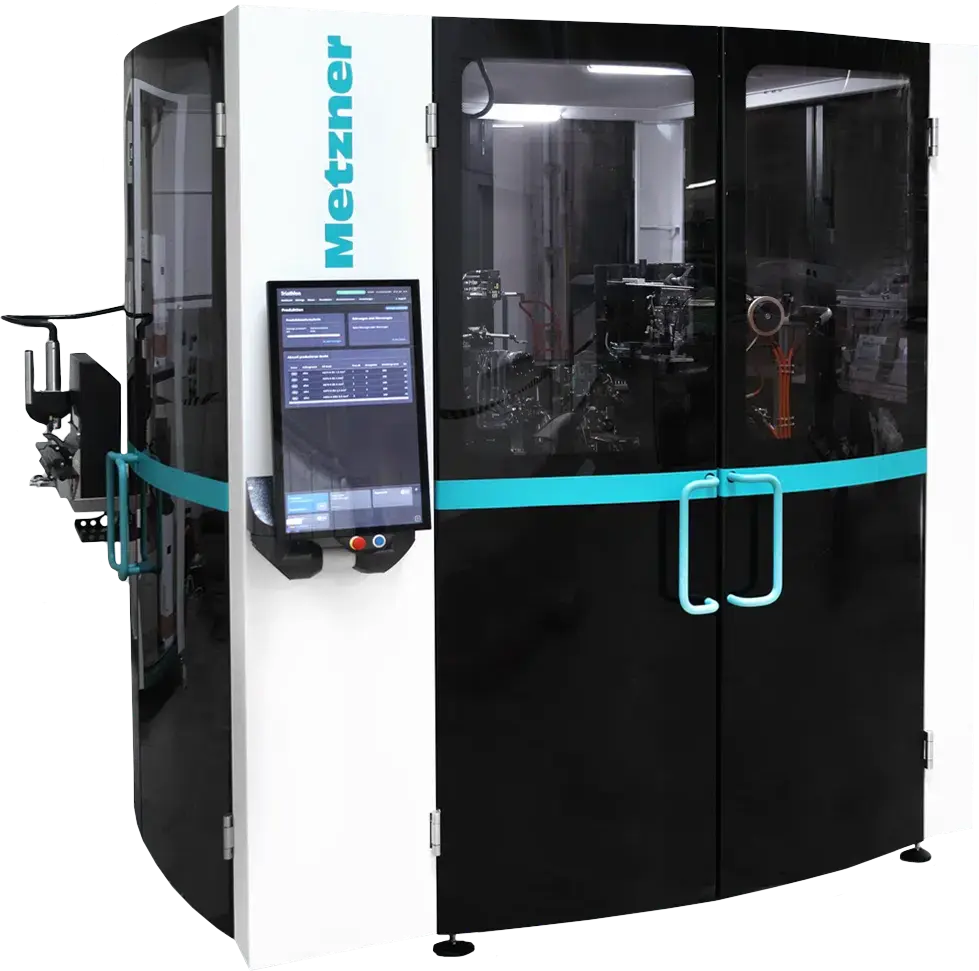

The Triathlon S and L are highly automated wire assembly machines that are revolutionizing the wiring process in switch cabinet construction

You supply complete, ready-to-install wire sets – assembled, labeled, and in the correct wiring order – saving considerable time and money.

Maximum productivity – up to 450 wires per hour

Triathlon L

For maximum productivity

Triathlon S

Ideal for small and medium-sized series

Both models dispense wires as chain bundles or via wire magazines.

Fully assembled, ready-to-install wires

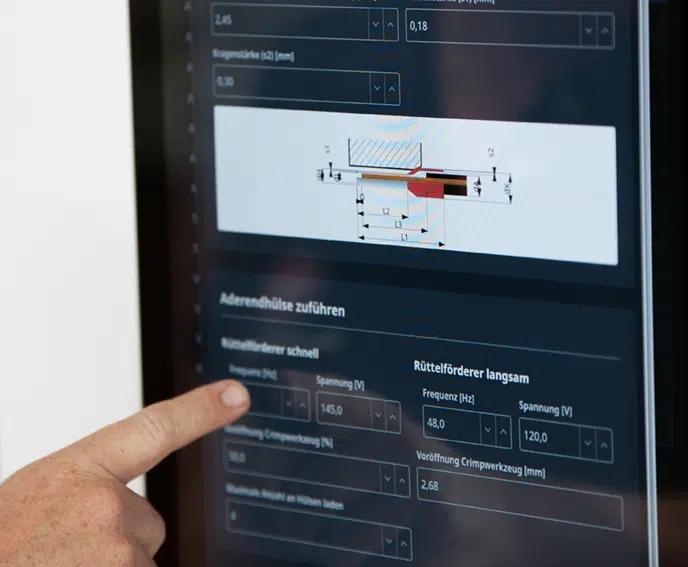

Triathlon processes all wires for a control cabinet project fully automatically

Crimping with ferrules (0.5–6 mm², 8–18 mm)

Cut to desired length

High-contrast, inline labeling using modern inkjet printers

Optionally fully or partially stripped

Output in correct wiring sequence for direct mounting

Intelligent automation & fast wire change

A special highlight of the triathlon series is the RFID-controlled automatic wire change.

Optionally, a wire storage system with up to 12 bundles/reels can be integrated, which automatically detects wires and keeps them ready for use. The L version can even process up to 3 storage units simultaneously.

Significant time and cost savings – fast ROI

The triathlon solutions pay for themselves even with small series sizes.

Why triathlon?

Your advantages at a glance

Fully automatic wire assembly

Inline labeling without wasting time

Automatic, RFID-controlled wire change

Reduction of assembly errors

High flexibility with wire variants and magazine options

Faster processes and improved cost-effectiveness