Wire Crimping processes – precise processing methods,

ensuring airtight connection of contact materials to cables.

Individual solutions for demanding industries

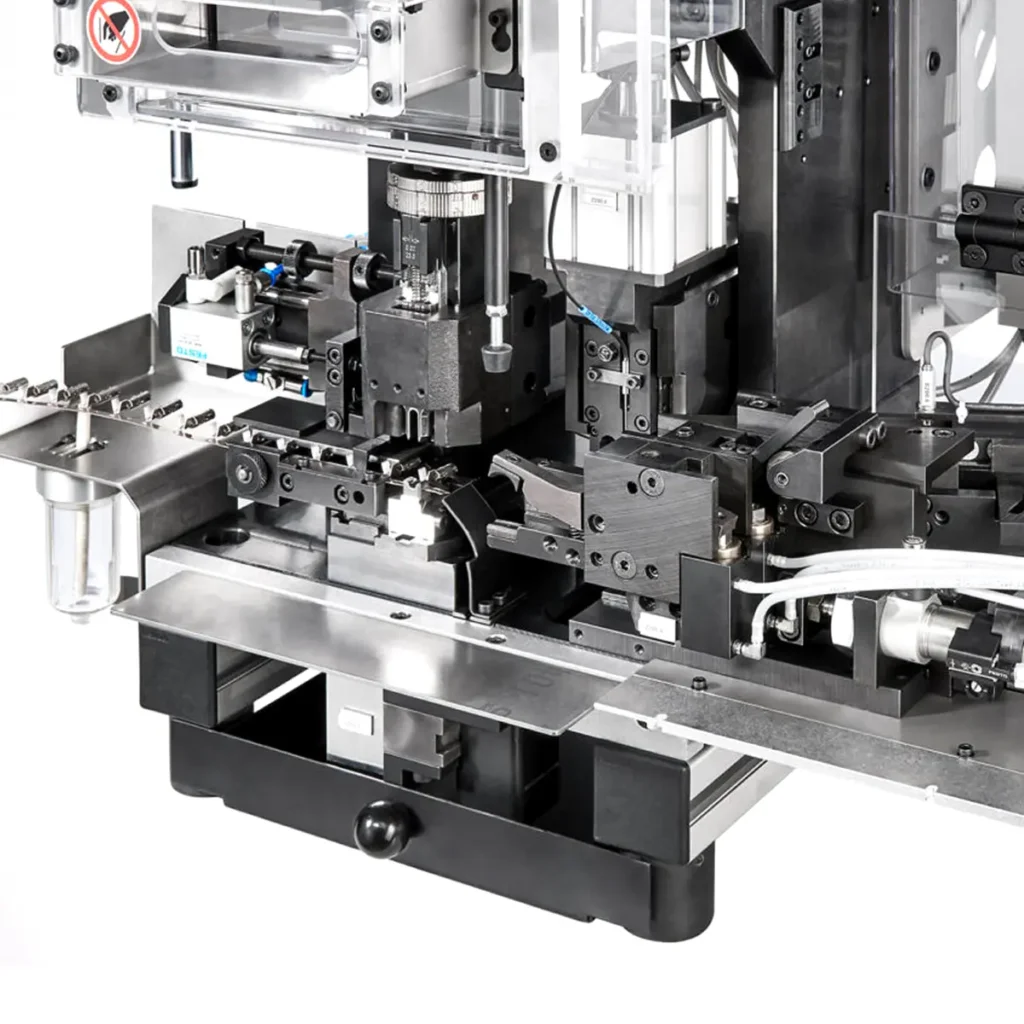

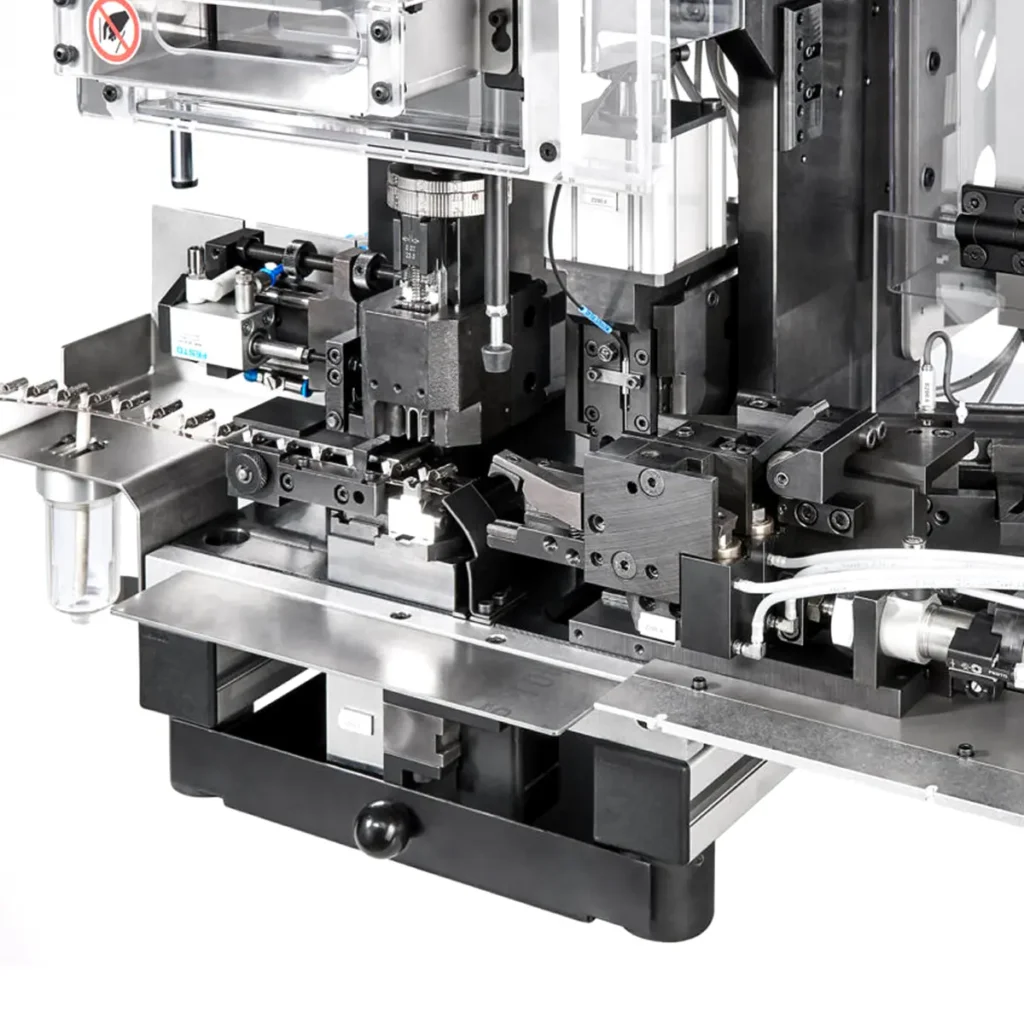

Precision presses in combination with high-quality quick change tools are your guarantee for an optimal production process! All sizes of crimping presses are available for processing different cross sections.

Quick change tools are manufactured individually, that means according to the specific terminal. They are used in the following industries:

We care for the wide range of spare and wear parts and contribute to the smooth and hassle-free cycle of your production process.

The ultimate wire crimping solution

Schäfer offers fully automatic crimp machines for high productivity and various applications. On a modular platform different variants of Megomat machines were developed, to achieve maximum flexibility and meet customer specific requirements.

Automatisieren Sie Teile Ihres Crimp-Prozesses!

Schnellwechsel-Werkzeug

Crimp-Werkzeug für alle Kontaktarten und Dimensionen, als Stand-alone verwendbar, kombinierbar mit allen gängigen Crimp-Pressen.

Crimp-Pressen

Im Crimpkraftbereich 2 – 15t, auch als Basis für Sonder-Crimpanlagen.

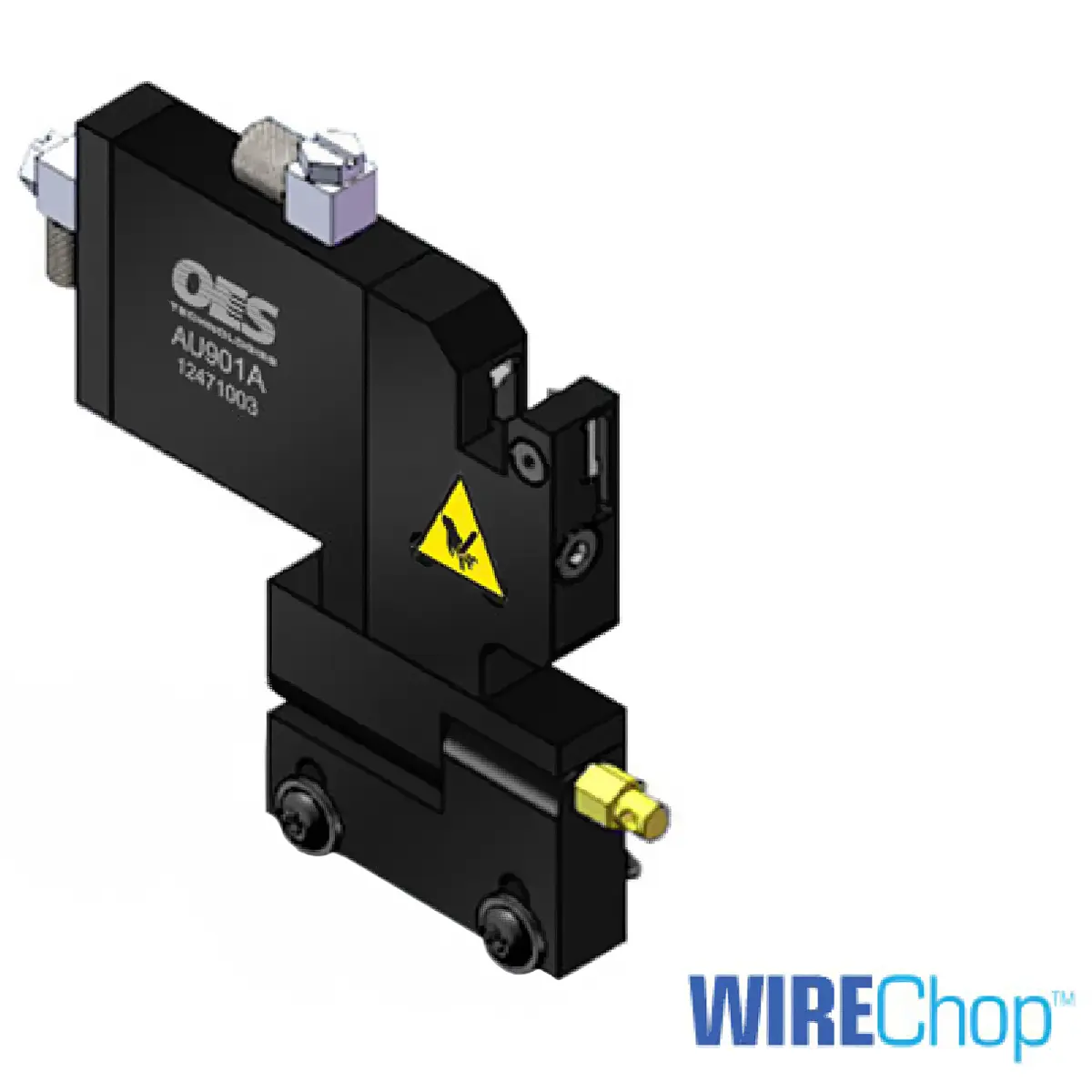

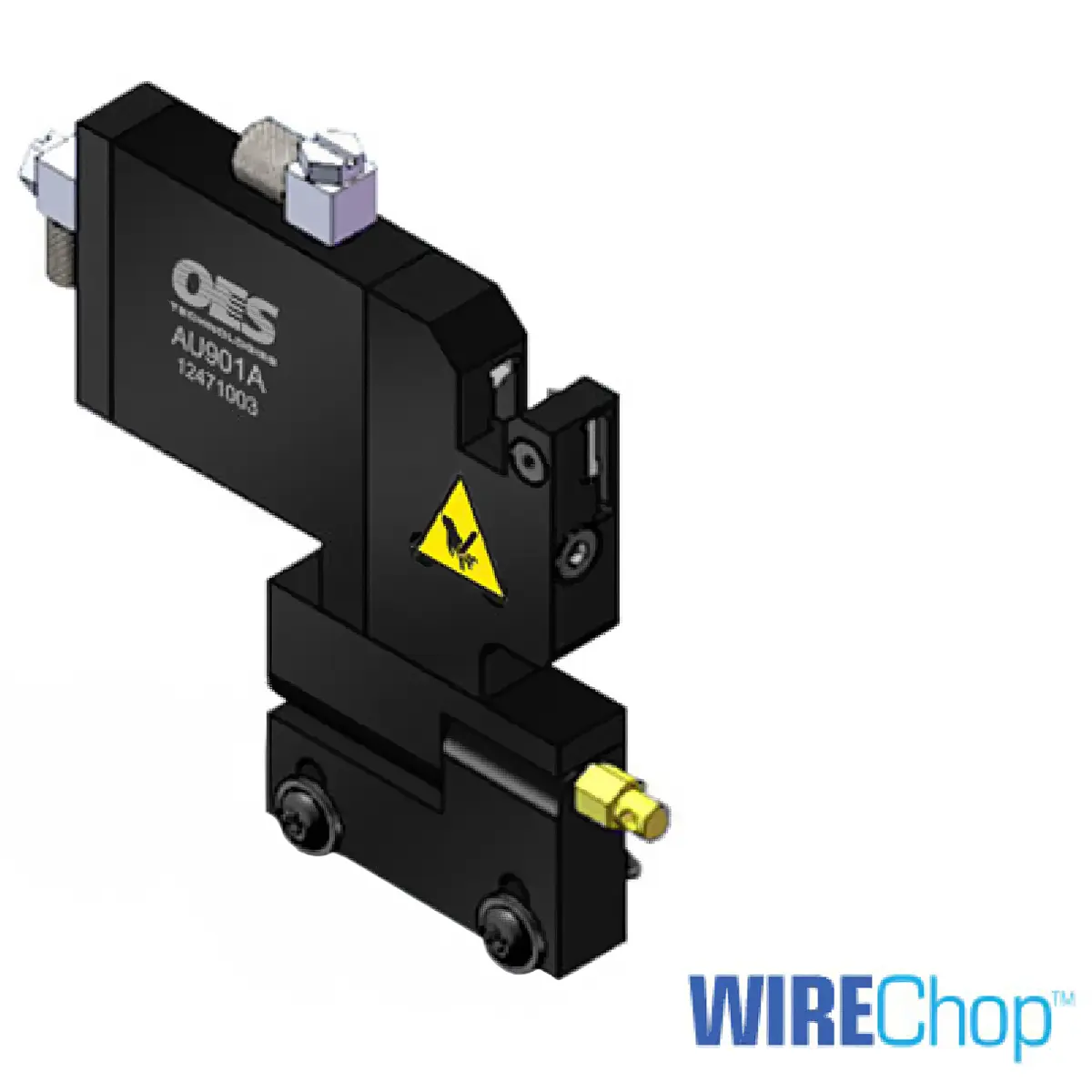

WireChop™ Schlechtteilschneider

Das “WireChop™” System verhindert, daß schlecht gecrimpte Verbindungen in die Produktionslinie gelangen. Es erkennt in Kombination mit einem CFM (Crimp Force Monitor) schadhafte Teile und zerstört diese sofort oder nimmt diese mittels Klemmung aus dem Prozess heraus.

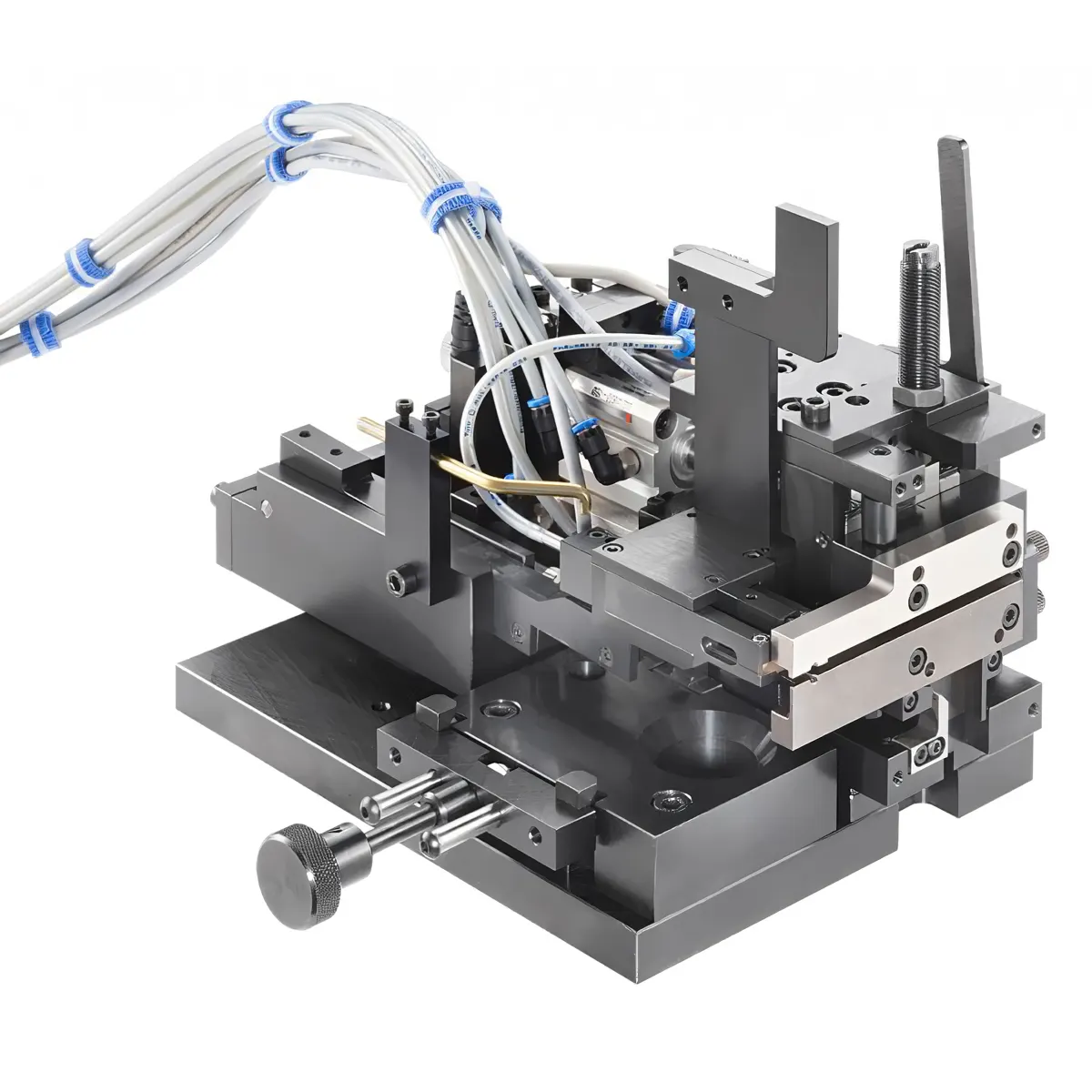

Abisolier-Einheit

Die Verbindung zwischen Abisolier- und Crimpprozess.

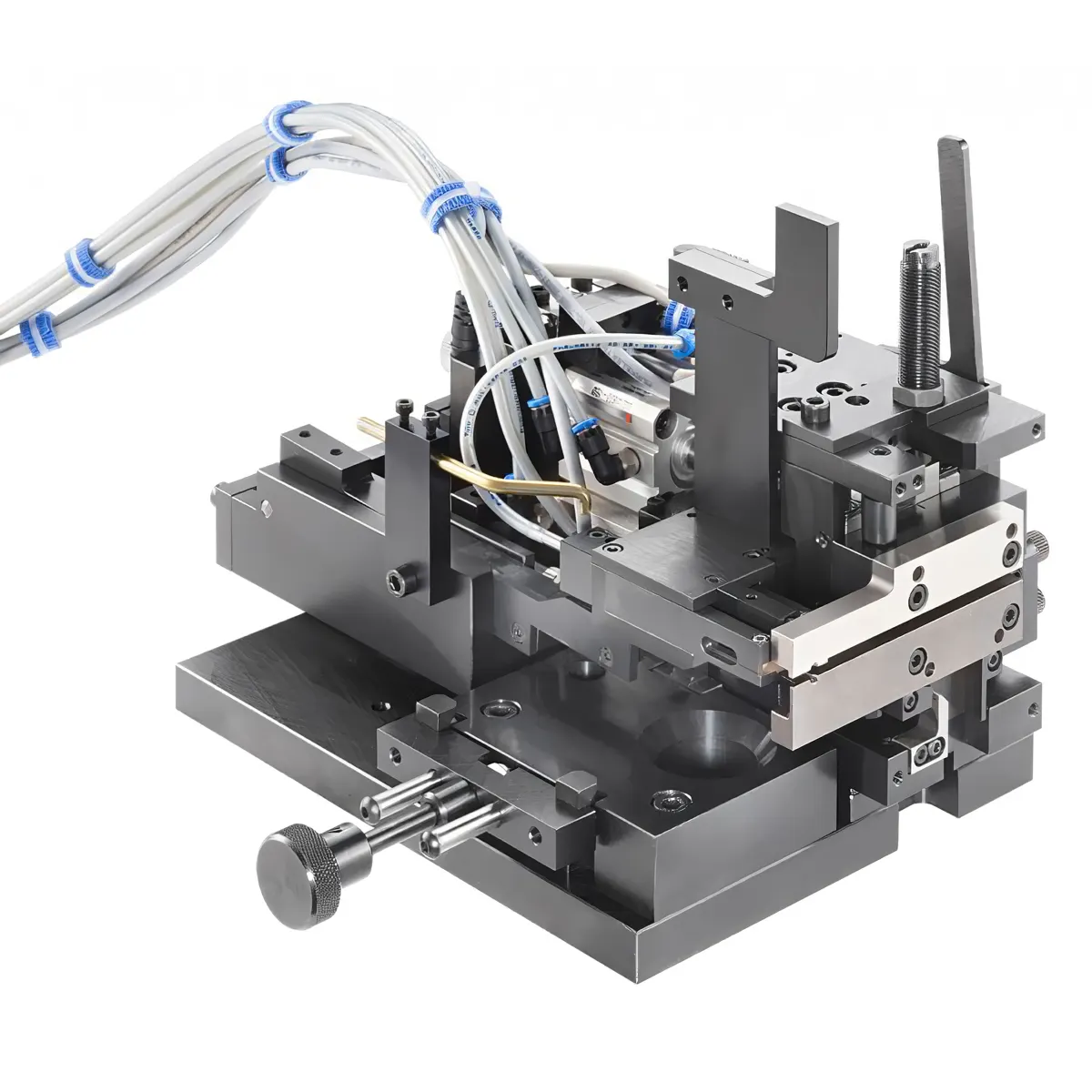

Automatisierte Crimping‑Einheit

Voll- und teilautomatisiert, für Spezialleitungen wie verdrillte Leitungen in Kombination mit Gehäusemontage, Widerstandsschweißen.

Automate parts of your wire crimping process!

Quick-change-tool

For all terminal types and dimensions, as stand-alone or in combination with any current crimp presses.

Crimping press

Crimp Force range 2-15t, forms also basis for automated crimping units.

Crimp portfolio PDF download

WireChop™ Waste‑Cut module

Separates faulty crimps from correct ones. Monitoring your wire crimping process and knowing when manufacturing conditions are changing is critical in detecting errors, and eliminating unnecessary scrap.

Automated crimping units

Full- and semi-automated, for processing of special cables, twisted wires in combination with block loading.

Stripping unit

The connection between stripping and crimping process.

If you’d like to speak with a CETEC Systems specialist, fill out the form and we’ll contact you.

Click here!