The aim of automated shrinking of shrinking tubes is to reduce processing time and increase quality

Efficiency and safety

Shrinking tubes are used to protect and isolate the terminals and welded junctions of the harness. What are the benefits in using heat shrinking systems instead of using a manual process?

Benefits include:

Time saving: During the shrinking process, the operator is free to perform other tasks.

Process control: Reliability and consistency of the process by monitoring and controlling the system’s temperature, shrinking time and position of the sleeve.

Safer: The operator is protected against injuries.

The ideal hot-air basic solution for simple line panel applications!

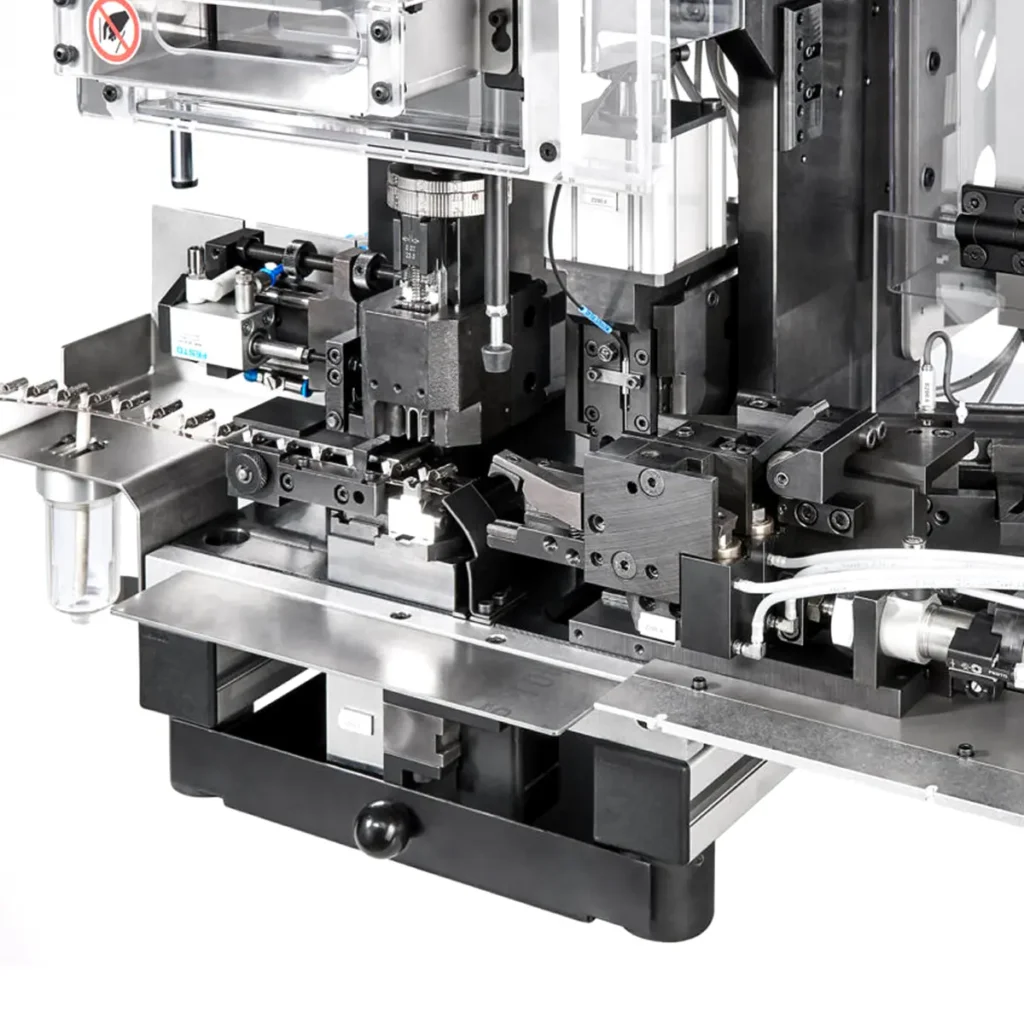

The STCS-L is a machine for processing heat shrink tubes, based on hot air devices. It´s designed for line panel applications and can process one part at a time. All controls and interfaces are integrated in a compact box, which includes the hot air tool and clamps. Customizable shrinking chamber.

Heat Shrink Systems based on Hot Air or Infrared technology

STCS-B – HotAir shrinking tube control system

Designed for workbench applications – can process one part at a time. Supplied with a standard shrinking chamber of 15x50mm, which can be customized.

Open data sheet

STCS-L – HotAir shrinking tube control system

Mounted on panel using a suction vacuum pump. Supplied with a standard shrinking chamber of 15x50mm, which can be customized.

Open data sheet

STCS-VMir – Infrared Workbench shrink system

A heat shrink system, based on infrared technology. It is designed for workbench applications and can process several parts at the same time. The same machine can be used on several applications, since it is equipped with a fast exchangeable shrinking chamber system.

Open data sheet

STCS-LC – Shrink tunnel

The STCS-LC (Longitudinal Conveyor) is a heat shrink system based on infrared resistors, which is able to process several and different types of parts at the same time. Different from any other, the LC guarantees flexibility by shrinking virtually almost everything. From normal splices to special applications, one single machine can do it all.

Open data sheet

STCS-BLT Splice testing unit

An easy but reliable device to test the sealed splice connection by applying a bubble test and a leakage detection.

Open data sheet

If you’d like to speak with a CETEC Systems specialist, fill out the form and we’ll contact you.

Click here!