Meet the industrial demand for accompanying quality control by completing a thorough quality inspection and documentation of your production sequence!

Process reliability and cost reduction

Quality inspection and quality control entails several benefits for you, when done systematically and in continuous quality:

Professional and transparent documentation of quality control to your end customers.

Cost reduction due to minimization of claims or reworks.

process-safe work environment for your employees.

Enhancing your competitive position through steadying and continuous quality.

Quality inspection made easy!

Fastest change-over until lot size 1

Flexible positioning to check 1 cm raster modules

Easy handling from Plug-and-Play easyCATS software

Testing systems

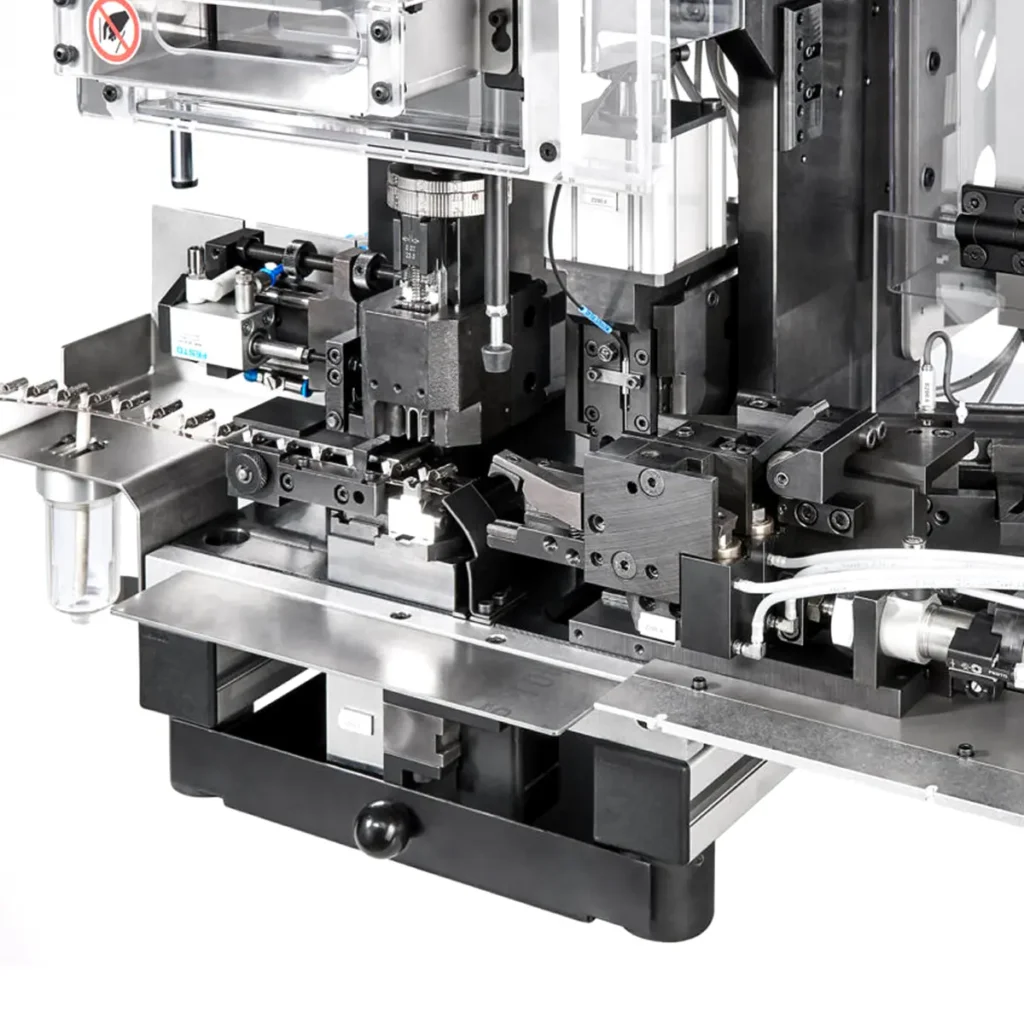

i-CAT Cable testing system

The only cable testing system worldwide with a position-detection checking module and very fast changeover system to different wire harnesses.

Our portfolio PDF download

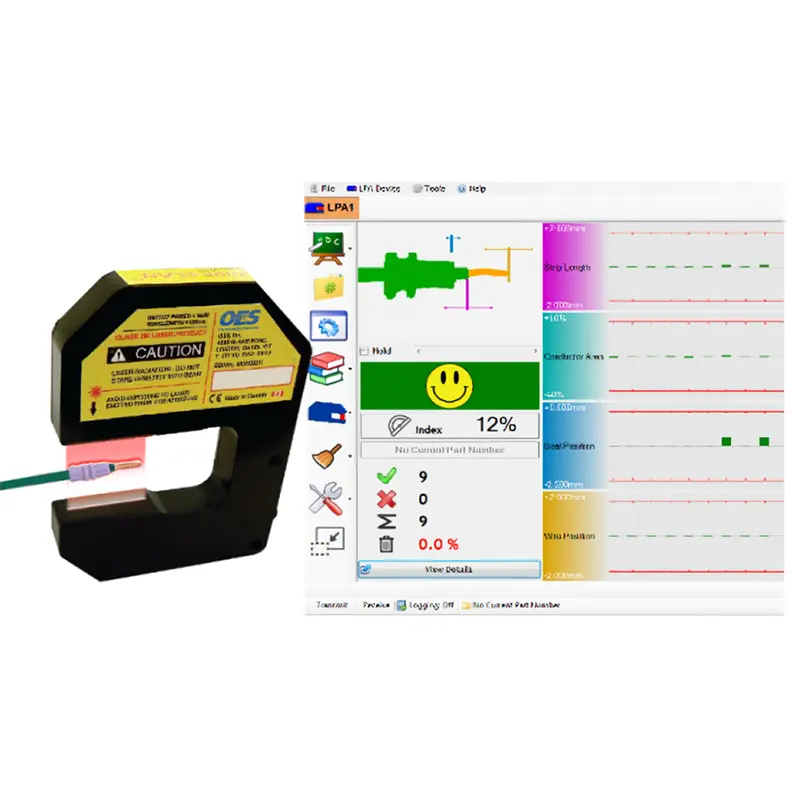

Crimp Force Monitor

Controls in every crimp sequence the crimp height, missing wire, missing litz wire, too short stripping.

Our portfolio PDF download

Contact a CETEC Systems® specialist

Contact us

Micrograph Laboratory

Compact tabletop laboratory for cross section analysis of crimped contacts.

Wire Scan

- Detects common strip defects

- Detects common seal insertion defects

- Designed for integration onto existing and new wire processing equipment

If you’d like to speak with a CETEC Systems specialist, fill out the form and we’ll contact you.

Click here!