What are the challenges with manual Heat-Shrinking?

The biggest problem within the Heat-Shrinking process is the complexity that can lead to the differing results in quality. In most cases you need more than just experienced employees to achieve consistent end results. In many production plants shrinking tubes are used to protect and isolate the terminals and welded junctions of the harness.

Those shrinking tubes are processed at a work-bench with the use of a hot-air unit. This kind of work procedure is time-consuming, complex and costly in energy. A lot of focus needs to be directed towards the consistent conditions of the shrinking process – and that is where the challenge lies:

„It depends on the ability of the employee to consistently apply the correct temperature, to consistently keep the right distance between hot-air unit and shrinking tube and to consistently apply the exact same length of time.“

The overall physical state of the employee and shift changes become important influencing factors for the quality of the end results!

How do you achieve ongoing, consistently good quality within the Heat-Shrinking process?

Undoubtedly you want to meet your customer´s high expectations, thus gaining competetive advantage, if you succeed. One way to achieve this is by using process reliable sytems like MECALBIs Heat-Shrinking Control Systems.

Heat-Shrinking Systems offer the following advantages:

- Constistent temperature

- Consistent processing time

- Consistent distance between the heatsource and the shrinking product

Within our product portfolio we encourage you to have a look at the following:

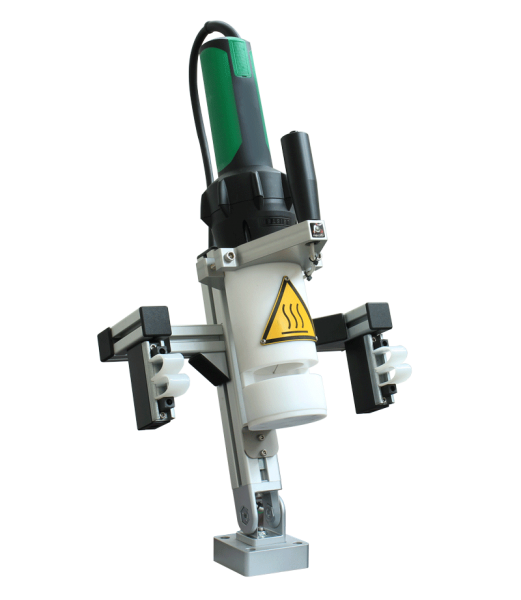

Hot-Air Shrinking Systems:

Hot-Air Shrinking Systems can be individually programed by means of a controller. Temperature, time as well as individual programs can be easily regulated. Furthermore with individually adjusted shrinking chambers several harnesses can be processed at once. With this an ongoing good quality can be achieved.

Infrared Shrinking Systems:

Infrared Shrinking Systems stand out due to their better power efficiency as well as because of the faster heating of the shrinking tubes. Keeping the quality consistently high, Infrared Shrinking Systems are available in sliding table or tunnel system versions, where large numbers of shrinking tubes can be processed.

Both system solutions ensure, by means of signals and switch-off possibility, that the end product is not damaged. With consequent use of one of those two versions you will see enormous time-savings in a short period of time!