Crimping is a crucial technique in the electronics and cable manufacturing industries, enabling the formation of secure and reliable connections between wires and terminals. The term “crimping” originates from the process of compressing or deforming materials to join them together. This method is widely preferred due to its efficiency, reliability, and cost-effectiveness, especially in mass production environments. In this article, we will explore what crimping is, how it works, and its significant role in cable production.

What is Crimping?

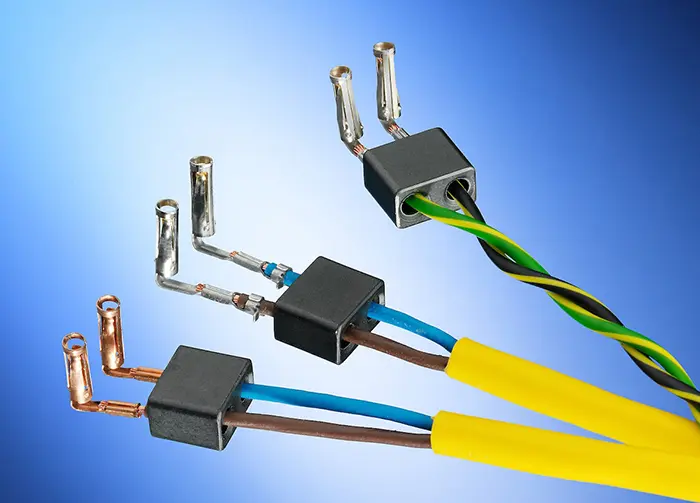

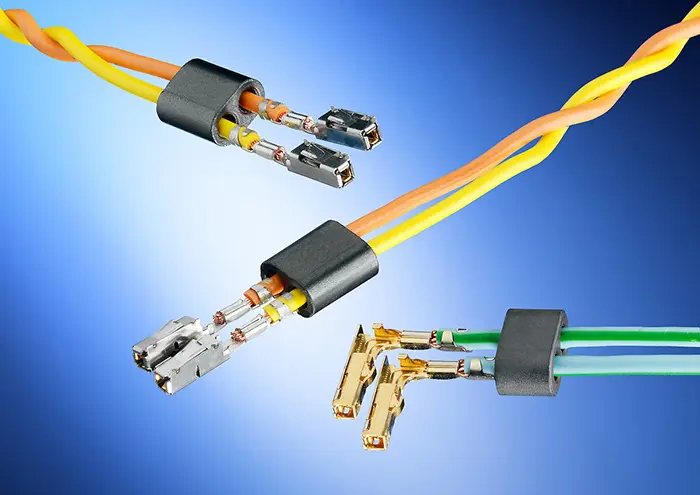

Crimping refers to the process of joining two materials, typically an electrical conductor (like a wire) and a terminal, by plastically deforming one or both of them. The goal is to create a stable mechanical and electrical connection without the need for soldering or other bonding methods. This technique is commonly used in various industries, including electronics, automotive, telecommunications, and aerospace.

The Mechanics of Crimping

The crimping process involves several key steps, each critical to ensuring a successful and durable connection:

Cable Preparation: The first step in crimping is preparing the cable. This involves stripping a specific length of insulation from the wire to expose the conductor. Care must be taken during this step to avoid damaging the wire strands, as any damage could compromise the integrity of the connection.

Positioning the Wire in the Crimp Terminal: Once the wire is stripped, it is inserted into a crimp terminal or contact. This terminal is typically made of a conductive metal, such as copper or brass, which provides excellent electrical conductivity. The wire must be positioned correctly within the terminal to ensure that it is securely held during the crimping process.

Applying Crimp Pressure: The crimping itself is performed using a crimping tool or machine that applies a specific amount of pressure to deform the terminal around the wire. This pressure must be precisely controlled to ensure that the terminal grips the wire firmly without damaging it. The deformation of the terminal creates a strong mechanical bond, while the close contact between the wire and terminal ensures good electrical conductivity.

Quality Control and Testing: After crimping, the connection is typically tested for both mechanical strength and electrical conductivity. This may involve visual inspections, pull tests to assess the mechanical bond, and resistance measurements to ensure low electrical resistance.

Why Crimping?

Crimping offers several advantages over other connection methods, making it a preferred choice in many applications:

Speed: Crimping is a fast process, especially when compared to soldering. It does not require any heating time and can be completed in a single step, making it highly efficient for mass production.

Reliability: A properly executed crimp connection is extremely reliable. It offers high mechanical strength, ensuring that the connection remains intact under stress, and excellent electrical conductivity, reducing the risk of power loss or interference.

Cost-Efficiency: Crimping is cost-effective due to its low material consumption and the absence of additional consumables like solder or flux. The process also requires less skilled labor compared to soldering, further reducing costs.

Consistency: In industrial settings, crimping offers high repeatability, ensuring consistent quality across large production volumes. Crimping machines can produce thousands of identical connections with minimal variation.

Crimping in Cable Production

In cable production, crimping is an indispensable process that ensures reliable connections in a variety of applications. Whether in automotive wire harnesses, telecommunications networks, or complex aerospace systems, crimping provides the necessary durability and reliability required for these critical components.

The Crimping Process in Cable Manufacturing

The production of cables and wire harnesses, which often involve numerous electrical connections, requires a precise and reliable crimping process. The steps involved in crimping within cable production are as follows:

Material Selection and Preparation: The process begins with selecting the appropriate materials, including the type of cable, crimp terminals, and crimping tools or machines. The materials chosen must meet the specific requirements of the application, such as current capacity, environmental conditions, and mechanical stress.

Automated Crimping: In large-scale cable production, automated crimping machines are commonly used. These machines can perform the entire crimping process in a fully automated manner, including cutting the cable to the required length, stripping the insulation, and crimping the terminal. Automation ensures high throughput and consistent quality across large batches of cables.

Quality Assurance: After the crimping process, the cables undergo rigorous quality checks. These include visual inspections to detect any visible defects, pull tests to verify the mechanical strength of the crimped connection, and electrical tests to ensure proper conductivity and low resistance.

Documentation and Traceability: In modern cable production, every batch of crimped connections is documented to ensure traceability and compliance with industry standards. This documentation includes details about the materials used, the crimping parameters, and the results of quality tests. This level of traceability is crucial for industries like automotive and aerospace, where safety and reliability are paramount.

Applications of Crimping in Cable Production

Crimping is widely used across various industries, each with its unique set of requirements:

Automotive Industry: In automotive manufacturing, crimping is essential for creating reliable connections within wire harnesses that link various electronic components in a vehicle. These connections must withstand vibration, temperature fluctuations, and other harsh conditions.

Telecommunications: In telecommunications, crimped connections are used in cables for networks, telephone lines, and broadband systems. The integrity of these connections is critical for maintaining high-speed data transmission and reducing signal loss.

Aerospace: The aerospace industry demands the highest levels of reliability and durability. Crimping is used in wiring systems for aircraft and spacecraft, where the connections must endure extreme environmental conditions, including high levels of vibration, temperature extremes, and exposure to radiation.

Consumer Electronics: Crimping is also prevalent in consumer electronics, where it is used to connect various components within devices such as computers, smartphones, and household appliances. The method ensures that these devices function reliably over their intended lifespan.

Conclusion

Crimping is a fundamental technique in the electronics and cable manufacturing industries, providing a fast, reliable, and cost-effective method for creating secure connections. In cable production, crimping is critical to ensuring the integrity and performance of cables used in a wide range of applications, from automotive systems to telecommunications and aerospace.

The use of crimping machines and advanced quality control measures ensures that crimped connections meet the highest standards of reliability and durability. As technology continues to evolve, crimping remains a cornerstone of cable production, ensuring that critical systems function safely and efficiently across various industries.