Everybody is talking about electromobility! Crimping for electromobility means also new challenges for cable manufacturers and cable assemblers. It requires lines, that are well-adapted to this new process, such as high-voltage lines, which are suitable for this voltage-level category.

New Challenges ahead when Crimping for the Electromobility

Depending of the respective drive technology, voltage up to 400 volt are reached in modern automobiles. To be able to achieve this, the following is a must:

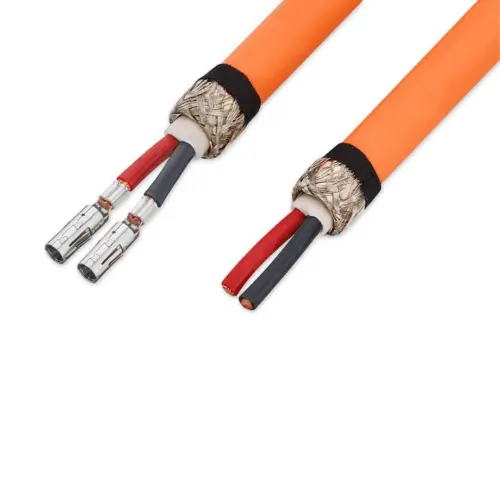

- intelligently manufactured cables and

- respective connection-systems.

Accordingly special processing techniques and processing machines are necessary. A whole set of novel crimp-machines are available for this purpose and the developement continues!

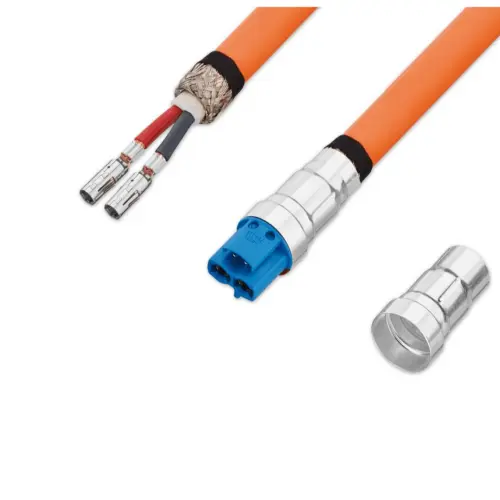

In this article we present 2 great options for HPS connection-systems, that are already successfully in use:

Crimping connectors

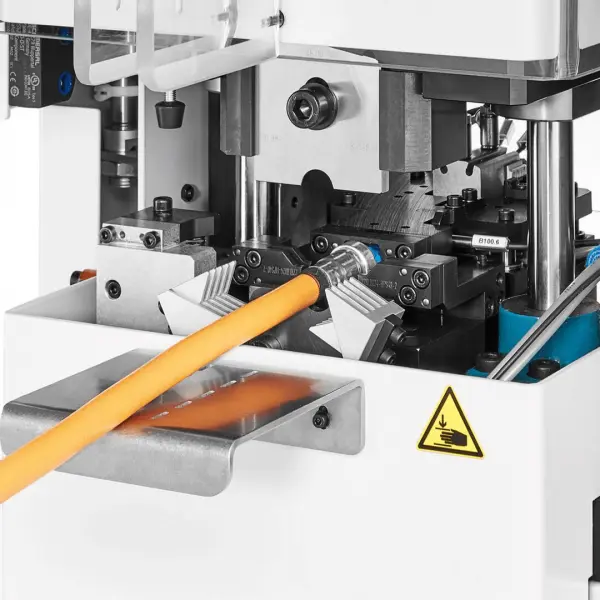

Half-automated crimping machines are used for the processing of those contacts. They are designed for stripping two-core sheathed cables and crimping in one go. The correct placement of the cable is ensured using Color detection and a Zero-cut module. The integrated bad-part cutter prevents the use of cables with incorrect crimps and the integrated crimp-force-monitor assures high quality.

Connecting of sleeves and cables

The process of crimping sleeves on sheathed cables is accomplished by the use of extensively equipped machines. The pre-assembled connectors on high-voltage cables are inserted by the operator. The machine starts automatically when the sensor in the stripping tool is touched. It is supported by the integrated crimp-force-monitor.

Together with our partner we support you with the integration of those new solutions into your exsisting process flows and care for continuing high quality.